Galvanizing

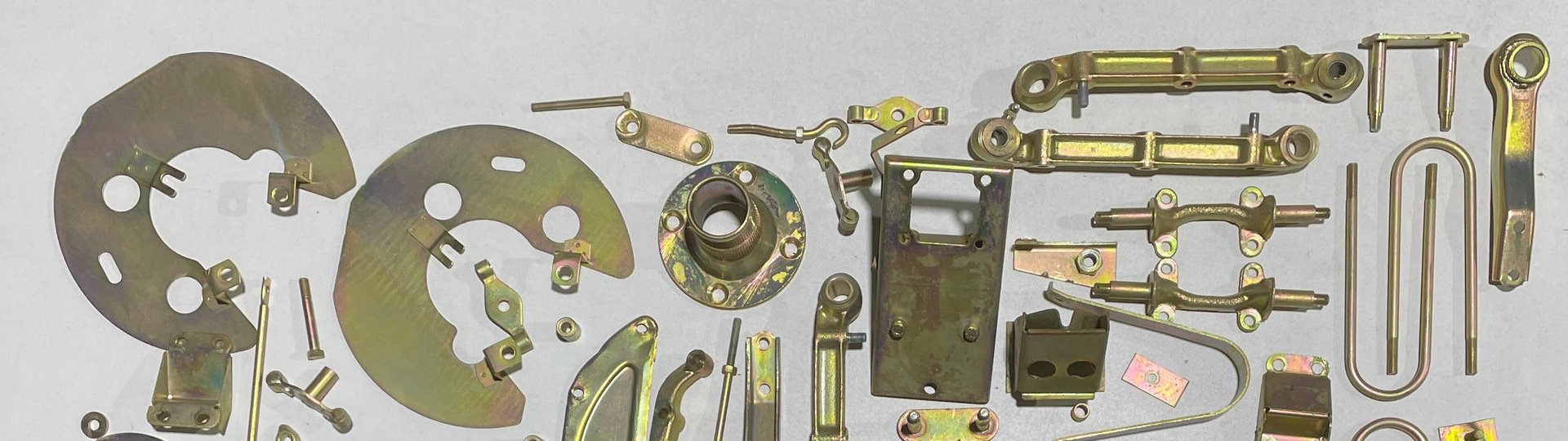

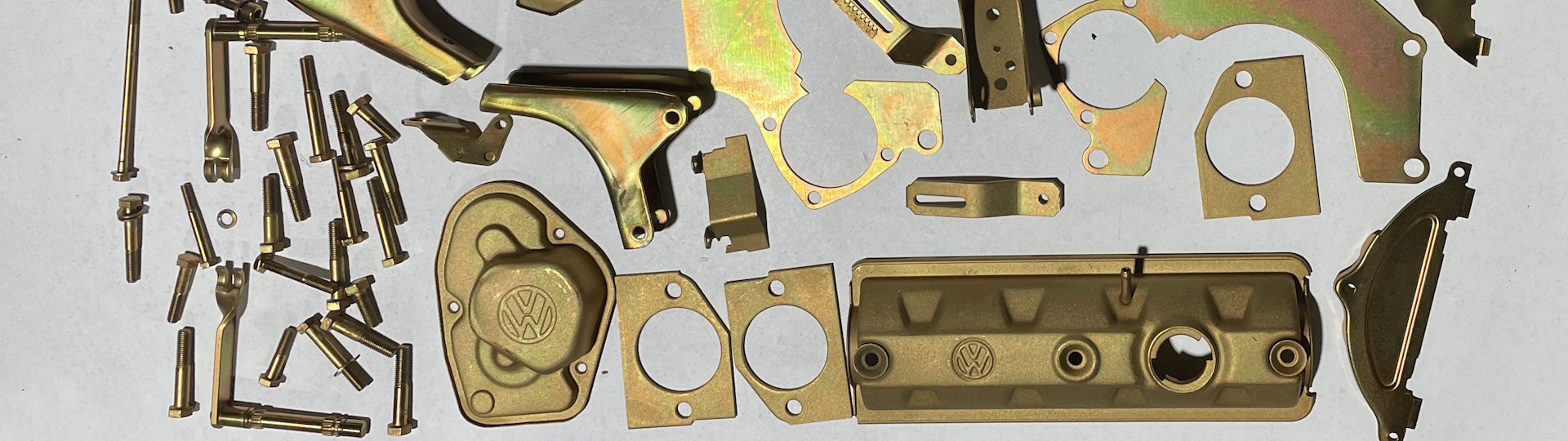

Galvanizing in both blue and yellow.

Including pretreatments such as degreasing, derusting etc. Our yellow and blue chromating process is the same as when it was used by today's oldtimers and youngtimers from car manufacturers such as: Mercedes, Porsche, BMW, Volkswagen, Audi, Jaguar, MG, Triumph, Rolls-Royce, Bentley, Citroën, Fiat , Maserati, Ferrari, Cadillac, Chevrolet, Ford, Opel, Buick, Pontiac, etc.

Parts are put into drums for small parts, such as bolts, and put up on racks for bigger parts.

When needed, parts are first chemically derusted or sandblasted. Old chrome and zinc coatings are chemically stripped.

Galvanizing process: 16 steps / positions Residence time in the baths from a few minutes to a few hours per bath:- electrolytic degreasing

- 2 x rinse

- derusting

- 2 x rinse

- electroplating

- 2 x rinse

- Activation

- 2 x rinse

- chromating in blue or yellow

- 2 x rinse

- Drying in ovens

Parts that where put up one racks are removed and packaged. Drum parts are centrifuged and dried. You can pick up your parts, or they can be shipped to you.